+91- 89284 84580

About Us

-

01.

About Us

Genstar Technik is a research & technology driven company, Pioneers in custom manufacturing of Liquid Silicone Rubber molding in India with 100 % German Technology.

Genstar capabilities for OEM projects include R & D, tooling, assembly for finish products etc.

Especially our expertise in Liquid silicone rubber injection molding (LIM), LSR + Plastic, LIM + Metal, LSR + LSR, Multicomponent molding with runner less cold runner technology.

We have executed many projects for Biodegradable implants plastics like PLA, BETA TCP, PEEK & many more, right from development stage to final execution.

Our core competency is providing complete Turnkey integrated solutions for mass production, Right from designing to tool development & Manufacturing needs.

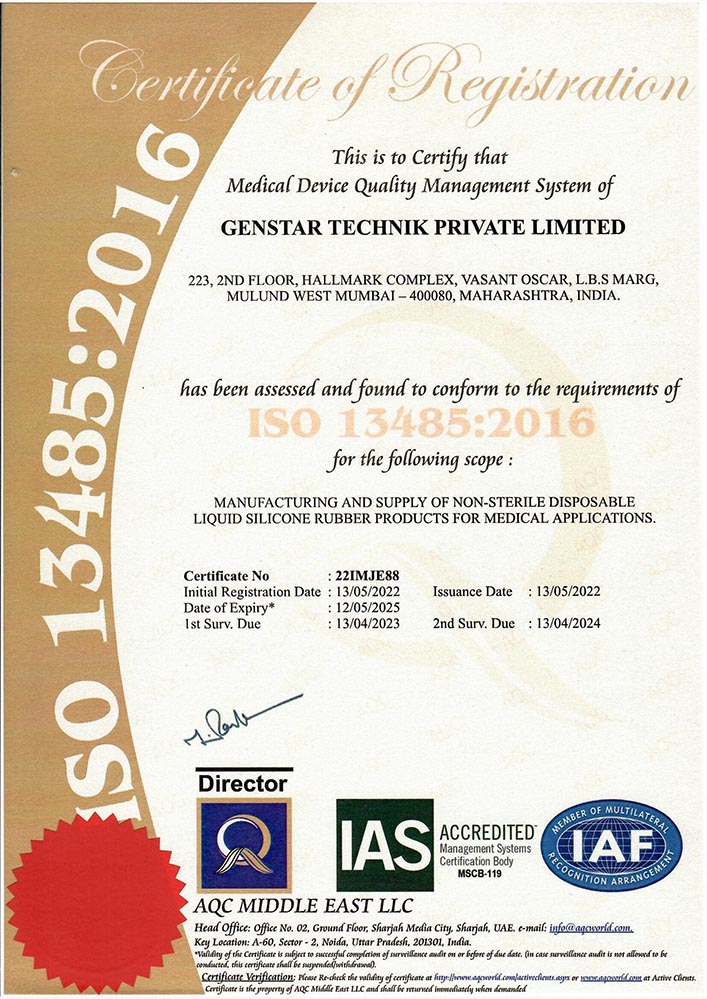

Genstar is certified under ISO 9001 and ISO 13485 system.

. -

02.

Driving Principals

We are a growth oriented organization that strives to achieve high competence through Technology to achieve high competence through technology & skilled manpower. It's our constant endeavor to create a world-class manufacturing environment servicing leading global companies adhering to strict quality assurance standards, Strong ethics & integrity.

We have a reliable process control mechanism & constancy in delivering products that exceed customer expectations.

We aim to be recognized as a world-class manufacturing company for Hi Tech silicone & plastic moulding.

We at Genstar constantly upskill our employees & upgrade our equipment in order to deliver reliable products each time, every time.

. -

03.

Mass production

At Genstar we never lose site of the fact that our job is to help you run at maximum efficiency and take advantage of the latest technological advances.

Often, those technology and automation innovations come about because of the high priority we place on developing technology in house.

This allows you to leverage the benefits that come with using the latest liquid silicone injection molding technology . why our engineers and highly specialized technicians - along with the professional team that oversees our overall operation - devote a significant amount of time staying current on emerging manufacturing processes and equipment.

Using innovation and automation, we can bring maximum efficiencies to your mass production manufacturing projects.

-

04.

Product development

An efficient NEW PRODUCT DEVELOPMENT process plays a key role.

Repeat customer means exceeded expectations. And that's not always easy to do when you're creating new products and identifying efficient ways to achieve a customer's new product objectives. One wrong turn can cost plenty in lost time and investment.

Genstar has more than 20 yrs of experience in product development for LSR products in applications like Baby Products , Connectors , LSR over molding on metal & plastics , Auto , Aerospace applications etc.

-

05.

Prototyping

There are several benefits producing a PROTOTYPE tool of your product before going on to the production stage.

The most obvious is that having prototype allows you to see what the actual product looks like.

We check design, & see how the product fits into your plan. If there are any problems or design flaws, they can be addressed before you move on.

The process of creating and evaluating a prototype can prevent that from happening.

A prototype is also an invaluable tool for generating interest and investment in your idea.

At Genstar , we use prototyping as a way to equip our customers with a competitive advantage.

Genstar can design, manufacture tooling and make prototype samples in o 45 days.

-

06.

We Are Certified